Publication

Advanced Redox Technology Lab

Publication

Advanced Redox Technology Lab

Journal papers

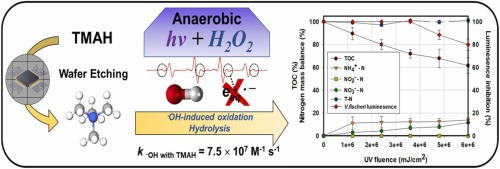

Semiconductor wastewater usually has a low level of dissolved oxygen and alcohol because ultra-pure water used in the process undergoes rigorous degassing and wafer development, respectively. In this study, we investigated the degradation mechanism of tetramethylammonium hydroxide (TMAH), a compound of concern in the semiconductor manufacturing process, during the UV-LED/H2O2 under initial nitrogen purging conditions to remove dissolved oxygen. The effect of the initial degassing was negligible due to the in-situ O2 production during the reaction. Along with hydroxyl radical (•OH), we first observed hydrated electron (eaq•-) formation by electron paramagnetic resonance (EPR) analysis in the presence of an excessive amount of tertiary butanol (t-BuOH), •OH scavenger, during the UV-LED/H2O2 reaction. However, the contribution of eaq•- on TMAH degradation was negligible compared to •OH which played a major role in TMAH degradation. The calculated reaction rate constant of TMAH with •OH was 7.5 × 107 M−1 s−1. From competitive kinetics, [•OH]ss and k •OH, TMAH value was found to be 7.1 × 10−13 M and 7.5 × 107 M−1 s−1, respectively. The optimum pH and temperature for TMAH degradation were pH 7 and 35 °C. Three demethylated amines (trimethylamine, dimethylamine, and methylamine), along with NH4+ and NO3- ions, were detected as the byproducts, implying that the main degradation mechanism of TMAH in this reaction is H abstraction by •OH-induced oxidation and hydrolysis resulting from the •OH-induced oxidation, and demethylation. Our result implies that the UV-LED/H2O2 reaction can be one of the options to treat TMAH contaminated water by recycling H2O2 produced in the semiconductor manufacturing process and lowering the energy consumption by using UV-LED.