Publication

Advanced Redox Technology Lab

Publication

Advanced Redox Technology Lab

Journal papers

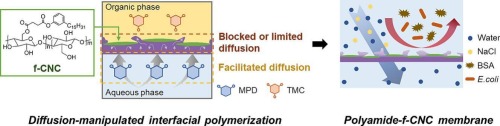

Polyamide (PA) thin-film composite (TFC) membranes, fabricated by interfacial polymerization (IP) process, have been widely used for the desalination process due to high water permeability with high water/salt selectivity. A number of advanced PA TFC membranes have been developed as more efficient alternatives to further improve separation performance and address the fouling problem of commercial membranes. Here, we utilized amphiphilic functionalized cellulose nanocrystal (f-CNC) having antibacterial property as a nanofiller material for the preparation of an advanced PA membrane system, featuring improved water permeability with high salt rejection ability. This strategy is inexpensive, scalable, environmentally friendly, and practically relevant, given that typical IP process with a renewable nanofiller was employed. The amphiphilic f-CNC manipulates interfacial diffusion of monomers upon IP process, thereby decreasing the effective PA layer thickness by 30 % (from ~377 nm to ~268 nm) and increasing water permeability by 44 % (from 1.26 L m−2 h−1 bar−1 to 1.82 L m−2 h−1 bar−1). In addition, the PA membrane with f-CNC showed improved antibacterial (~90 %) and antifouling properties (~84 %, FRR) due to the specific nature of f-CNC. This study provides insights for the development of thin, effective, and antibacterial, yet more green and scalable PA membrane alternatives to the conventional desalination membranes.